PREM BEAM

A composite Truss Prefabricated Beam, or PREM Beam, is a structural element, mainly subject to bending and shear, consisting of a reticular metal beam, with or without a prefabricated concrete bottom, embedded in whole or in part in a concrete casting on site.

The prefabricated part of a PREM beam, before the integrative casting in situ, is also identified as a "lattice" or "truss"; for this reason these beams are also identified as Composite Lattice girder Beams or Steel Truss Beams conglobated in a collaborating concrete casting.

The Italian acronym PREM(Prefabricated REticular Mixed) is a general name to which each manufacturer adds his own trademark to characterize the specifics of his product.

MORPHOLOGIES AND TERMINOLOGY

The main parts that form the lattice girder are:

- Bottom cord;

- Top cord;

- Web.

The bottom cord can be formed alternatively by:

- longitudinal bars incorporated in a prefabricated concrete bottom base;

- a large steel plate (bottom plate) and, if needed, longitudinal bars welded to it;

- longitudinal bars without any base neither made of concrete nor of steel.

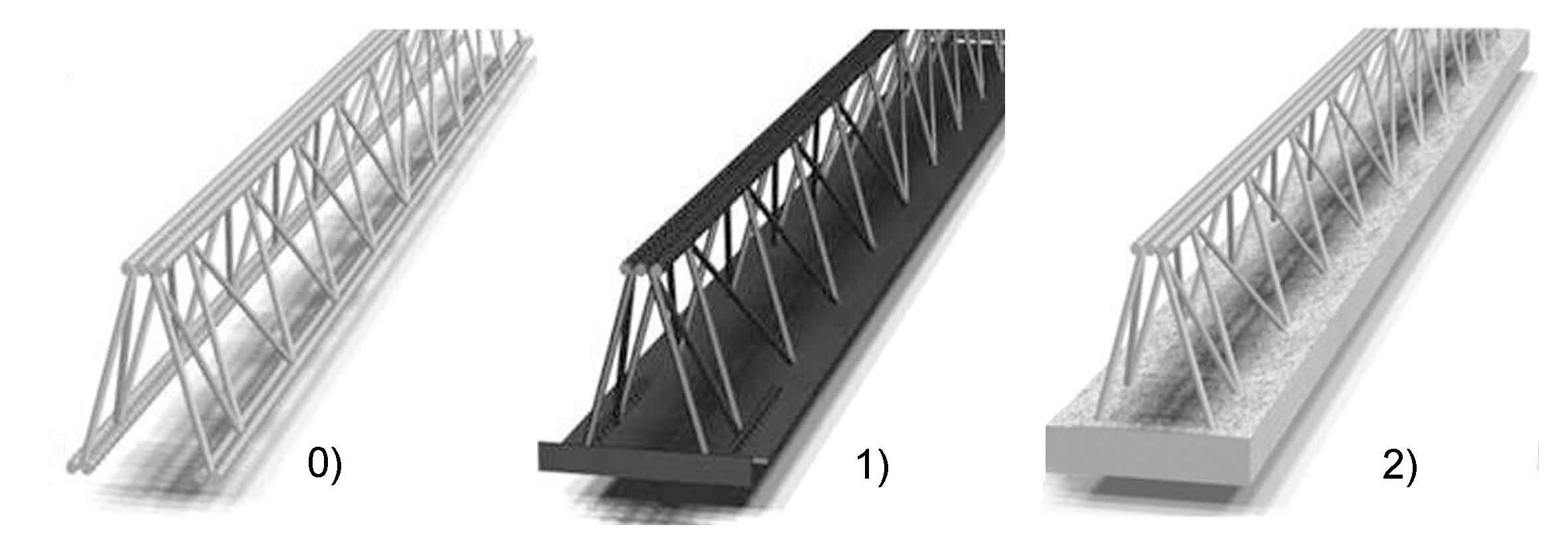

Depending on type of lower cord, PREM Beams are divided into the following three morphologies:

Fig 1 - PREM Beams morphologies: 0) without bottom plate, 1) with steel bottom plate, 2) with prefabricated concrete bottom base.

(Image from the "Technical and operative Guide for the Professional" by Assoprem)

STRUCTURAL CATEGORIES

In the specific Ministerial Procedures (Guidelines for the use of steel lattice beams incorporated in the integrative concrete casting and procedures for their Classification), the "classical" PREM Beams are framed either within the framework of reinforced concrete structures or within that of composite steel-concrete structures. Textually, the document reports:

"The phrase “lattice steel beams incorporated in the cooperating concrete casting” indicates, in general terms, a constructive technique including different types of lattice beams. First of all, it is necessary to define, with reference to Chapter 4, point 4.6 of the NTC (Construction Technical Norms) 2008, on the basis of the structural typology, in which structural category fits a specific model.

For this purpose, three categories are identified to frame each type of structure:

a) composite steel-concrete structures;

b) normal or pre-stressed reinforced concrete structures;

c) structures not attributed to principles, definitions, calculation models and materials of the two categories listed above.

Of the three categories mentioned above, the first two do not fall within the scope of the aforementioned point 4.6 of the NTC 2008, as they are expressly governed respectively by paragraphs 4.3 (composite structures) and 4.1 (reinforced concrete structures) of the same Rules, as specified below.

....

For all the aforementioned categories, two construction phases are identified: a first phase in which only the steel part is resistant and a second phase in which also the topping concrete has hardened."

It is therefore evident that the beams included in a) and b)categories, in compliance with paragraphs 4.3 and 4.1 of NTC, must follow respectively the requirements: for composite steel-concrete structures and for structures in reinforced concrete and prestressed reinforced concrete contained in the aforementioned paragraphs. But it is not enough. The same Ministerial Procedures, in fact, specify that, in order to be able to consider a PREM Beam belonging to one of the structural categories defined above, the individual producer of the beam must submit to the STC (Central Technical Service) a structural category assignment request adding to the same "appropriate descriptive and calculation report suitable to demonstrate compliance with the characteristics and requirements required for the specific category ".

Within four years, since the Ministerial Procedures were published, several producers have carried out this procedure for one of the three categories, but one producer only, the SD srl, has carried out the procedure for two structural categories: PREM Beams of category a) (composite steel-concrete) and PREM Beams of category b) (reinforced concrete), as shown in the Classifications Section of our site.

Below we represent the most characteristic specificities of the category a) and category b) PREM Beams.

FIELDS OF USE

The PREM beams biggest advantage is to adapt almost completely to any design hypothesis, geometrical and material, related to structural category or to actions (first and second phase), even more than reinforced concrete cast in place beams, not being affected neither by normalized profiles nor by binding formworks, nor by the materials.

The counterpart of this design freedom is that it is basically impossible to draw up utilization diagrams that would necessarily be restricted to an insignificant casuistry or constituted by an unmanageable multitude of different situations.

The only reliable way to manage them is with a specific software to be applied to each individual case.

STERCHELEGROUP PREM BEAMS MODELS

Each morphology and structural category has its own optimal field of application.

In Features and Benefits Section of our site, of our site, the Designer or the Contractor can find the best solutions for the project or jobsite, identifying the most suitable prefabricated beam and finding all its Technical Specifications by clicking on the following links:

PREM beams a2): a) category and concrete base

PREM beams a1): a) category and steel bottom plate

PREM beams a0): a) category and no bottom plate nor base